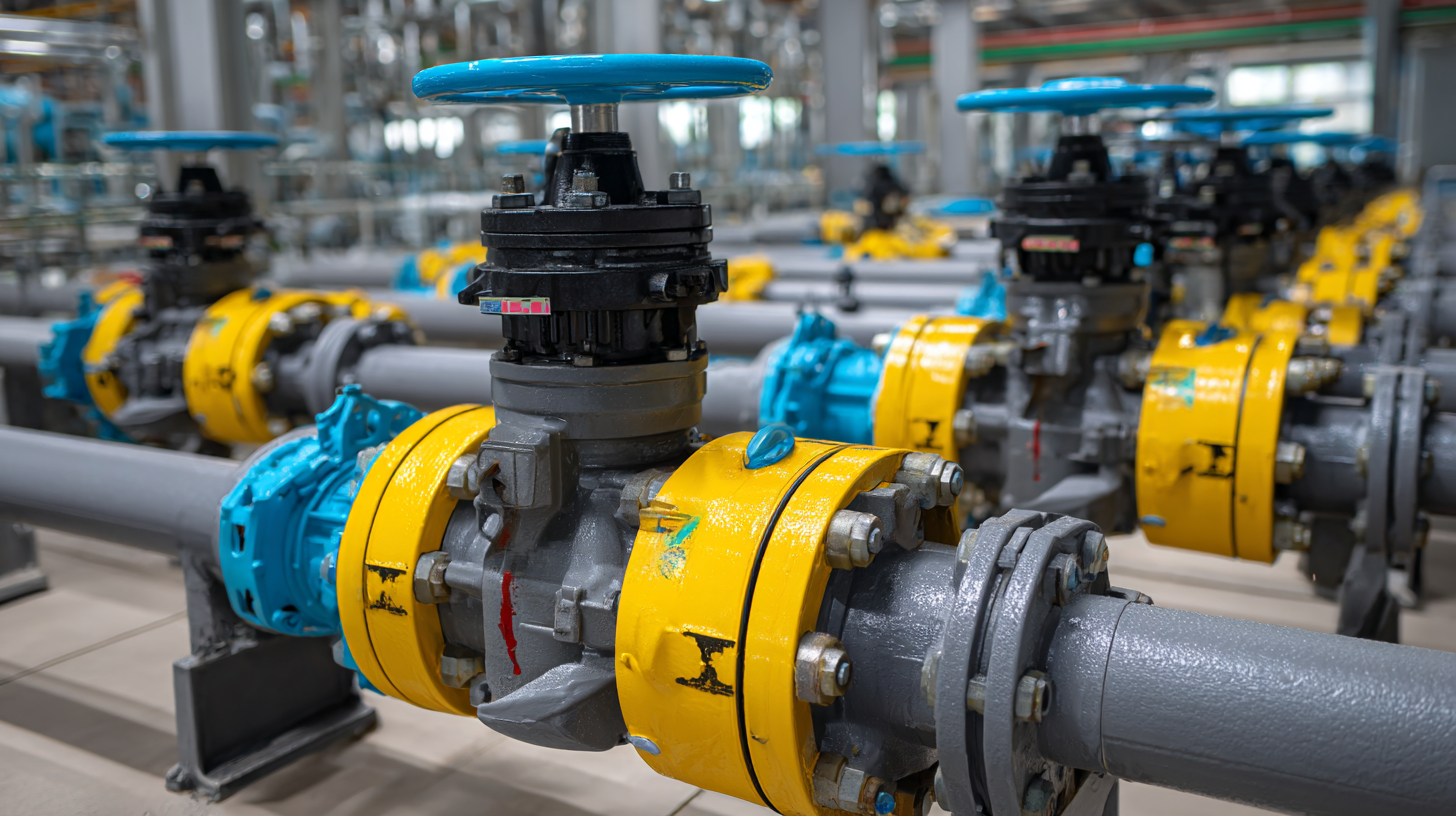

5 Reasons Why Actuated Butterfly Valves Are the Best Choice for Efficient Flow Control

In the realm of industrial flow control, the choice of valve significantly impacts efficiency and operational costs. Actuated butterfly valves have surged in popularity due to their superior performance and versatility in various applications. According to a report by MarketsandMarkets, the global valve market is expected to reach $93.8 billion by 2026, with actuated valves playing a pivotal role in this growth due to their ability to provide fine control and rapid response times. These valves are particularly advantageous in scenarios requiring quick modulation of flow, such as in HVAC systems and water treatment plants. Moreover, the U.S. Department of Energy estimates that optimizing flow control systems can lead to energy savings of up to 30%. Thus, integrating actuated butterfly valves into system designs not only enhances efficiency but also contributes to sustainability efforts, making them a top choice for engineers and manufacturers focused on advancing operational excellence.

The Precision of Actuated Butterfly Valves in Flow Regulation

Actuated butterfly valves have emerged as a leading choice for efficient flow control due to their remarkable precision in regulating fluid flow. According to a report by the Flow Control Institute, these valves can achieve flow regulation accuracy within ±1%, making them highly reliable in operations. This level of precision is crucial in industries such as water treatment and chemical processing, where even slight deviations can lead to significant operational inefficiencies. The design of actuated butterfly valves allows for quick response times, further enhancing their effectiveness in dynamic flow situations.

When considering the implementation of actuated butterfly valves, remember that consistent maintenance is essential for optimal performance. Regular inspections can help identify potential wear and tear, ensuring the integrity of flow control remains intact. Additionally, calibrating the actuator periodically will aid in maintaining the precise flow rate desired, thereby maximizing system efficiency.

Furthermore, it's beneficial to use actuated butterfly valves in applications with fluctuating pressure conditions. Their ability to handle varying pressures without compromising performance makes them suitable for a wide range of industries. With the continued advancements in valve technology, investing in actuated butterfly valves remains a smart choice for those aiming to enhance their flow regulation systems effectively.

Energy Efficiency: How Actuated Butterfly Valves Minimize Waste

Actuated butterfly valves offer remarkable energy efficiency in fluid control applications. Unlike traditional valve types, these valves utilize a simple disc mechanism that requires minimal energy input to operate. This efficiency stems from their design, which allows for quick and precise adjustments to flow rates, significantly reducing the energy wasted in excess pumping and distribution. As a result, industries can achieve a balance between operational demands and energy consumption, leading to lower utility costs.

Actuated butterfly valves offer remarkable energy efficiency in fluid control applications. Unlike traditional valve types, these valves utilize a simple disc mechanism that requires minimal energy input to operate. This efficiency stems from their design, which allows for quick and precise adjustments to flow rates, significantly reducing the energy wasted in excess pumping and distribution. As a result, industries can achieve a balance between operational demands and energy consumption, leading to lower utility costs.

Moreover, the automation of butterfly valves enhances their efficiency further by allowing for real-time monitoring and adjustments. Automated systems can optimize flow control based on actual demand rather than fixed settings, enabling facilities to adapt seamlessly to changing conditions. This capability not only conserves energy but also extends the lifespan of equipment and infrastructure by minimizing wear and tear associated with improper flow management. Through these mechanisms, actuated butterfly valves emerge as a top choice for organizations seeking to implement sustainable practices in their operations.

Versatile Applications: The Adaptability of Actuated Butterfly Valves

Actuated butterfly valves are increasingly recognized for their versatility across various industries, including water treatment, oil and gas, and HVAC systems. According to a recent report by the Global Valves Market Analysis, the demand for butterfly valves is anticipated to grow at a CAGR of 5.3% from 2021 to 2026, driven by their adaptability to different flow control scenarios. Their design allows for quick and efficient operation in both on-off and throttling applications, making them suitable for a range of environments requiring precise flow management.

Moreover, actuated butterfly valves can be easily integrated with modern automation systems, facilitating seamless control processes. A study by the American Society of Mechanical Engineers highlights that the use of actuated valves can reduce response times in fluid control systems by up to 30%, enhancing operational efficiency. This adaptability not only lowers operational costs but also improves safety during critical processes, proving that actuated butterfly valves are an optimal choice for industries demanding high reliability and dynamic performance.

5 Reasons Why Actuated Butterfly Valves Are the Best Choice for Efficient Flow Control - Versatile Applications: The Adaptability of Actuated Butterfly Valves

| Reason | Description | Applications | Advantages |

|---|---|---|---|

| Compact Design | Actuated butterfly valves have a smaller profile compared to other valve types. | Water treatment, HVAC systems | Saves space and reduces installation costs. |

| Quick Operation | They can be opened or closed rapidly, allowing for better control. | Chemical processing, food and beverage industry | Improves operational efficiency. |

| Low Pressure Drop | Minimizes pressure loss in the system. | Oil and gas pipelines, wastewater management | Enhances overall system performance. |

| Versatility | Can be used in a variety of applications and industries. | Power generation, irrigation systems | Adaptable to different environments and substances. |

| Cost-Effective | Lower cost in comparison to other valve types. | Mining, construction | Reduces overall project expenses. |

Enhanced Control Mechanisms for Dynamic Flow Conditions

When considering efficient flow control, actuated butterfly valves stand out for their enhanced control mechanisms, particularly in dynamic flow conditions. According to a recent report by the Flow Control Industry Association, these valves can achieve a higher degree of accuracy in flow regulation, offering control within ±1% of the desired flow rate. This level of precision is essential for industries such as chemical processing and water treatment, where even minor fluctuations in flow can lead to significant operational issues and increased costs.

Additionally, actuated butterfly valves are designed to respond quickly to changes in flow demands. The American Society of Mechanical Engineers (ASME) has reported that these valves can operate with a response time as brief as 2 seconds, allowing for rapid adjustments to varying process conditions. This responsiveness is particularly beneficial in systems where flow can be unpredictable, enabling operators to maintain optimal performance without compromising safety or efficiency. As industries continue to prioritize operational efficiency, the adoption of actuated butterfly valves is likely to become even more prevalent, reinforcing their status as a top choice for flow control solutions.

Durability and Maintenance: Long-Term Benefits of Actuated Butterfly Valves

Actuated butterfly valves have emerged as a preferred choice in industries ranging from water treatment to chemical processing, primarily due to their impressive durability and low maintenance requirements. According to a report by the MarketsandMarkets Brand, the global valve market is projected to reach $104.2 billion by 2026, with actuated butterfly valves being a significant contributor due to their robustness. These valves are designed to withstand high flow rates and pressure fluctuations, making them a reliable option for demanding applications. Their construction using resilient materials such as stainless steel or ductile iron ensures a long operational lifespan, significantly reducing the need for frequent replacements.

Moreover, the maintenance regime for actuated butterfly valves is notably simple compared to other valve types. A study published by the American Society of Mechanical Engineers (ASME) indicates that proper maintenance of butterfly valves can enhance their operational efficiency by up to 20%. This efficiency translates into both time and cost savings for businesses, as reduced downtime and maintenance interventions minimize operational disruptions. Additionally, many modern actuated butterfly valves come with features like automated diagnostics, further enhancing their maintainability and enabling predictive maintenance strategies that can preemptively address potential failures before they impact service.

Related Posts

-

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

Understanding the Functionality of Low Pressure Check Valves in Fluid Systems

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

Unlocking Performance with Best Stainless Steel Valves Comprehensive Technical Parameters and How to Choose the Right Fit

-

Ultimate Guide to Choosing the Right Electric Valves for Your Industrial Needs