Top 10 Benefits of Triple Offset Butterfly Valves for Your Projects?

The triple offset butterfly valve stands out in modern engineering projects. Its design offers impressive benefits, making it a popular choice. This valve type combines robust performance with innovative features.

One major advantage is its exceptional sealing capability. The triple offset design creates a tight seal that prevents leaks, even under high pressure. This feature is crucial for preserving system integrity. Another benefit is its ability to handle a wider range of temperatures and pressures. It performs well in various applications, from oil and gas to water treatment.

However, not all projects may require a triple offset butterfly valve. Depending on the application, simpler valve types could suffice. Users must carefully assess their needs. The importance of proper installation and maintenance cannot be overstated. A lack of attention in these areas can lead to performance issues. Overall, understanding the benefits and limitations of the triple offset butterfly valve is essential for making informed decisions.

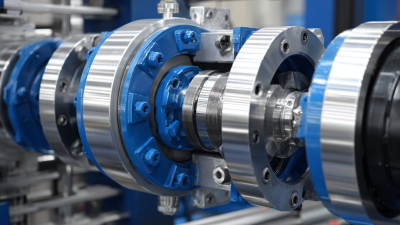

Key Features of Triple Offset Butterfly Valves

Triple offset butterfly valves are remarkable for various reasons. Their unique design greatly improves sealing efficiency. This feature minimizes leakage even under high pressure. With a three-dimensional disc rotation, these valves provide tight shut-off capabilities. They often outperform traditional valves in terms of durability and longevity.

Another key feature is their versatility in applications. They can handle a wide range of fluids, including gases and slurries. The lightweight design makes installation easier. However, it is crucial to ensure proper sizing. Miscalculating valve dimensions can lead to operational issues. Properly maintained valves can significantly reduce downtime and maintenance costs over time.

Material selection is equally important. Triple offset butterfly valves can be constructed from various materials. Stainless steel, for instance, offers resistance to corrosion. However, choosing the right material for specific environments can be challenging. Users must consider factors like temperature and chemical exposure. The right balance is essential for optimal performance.

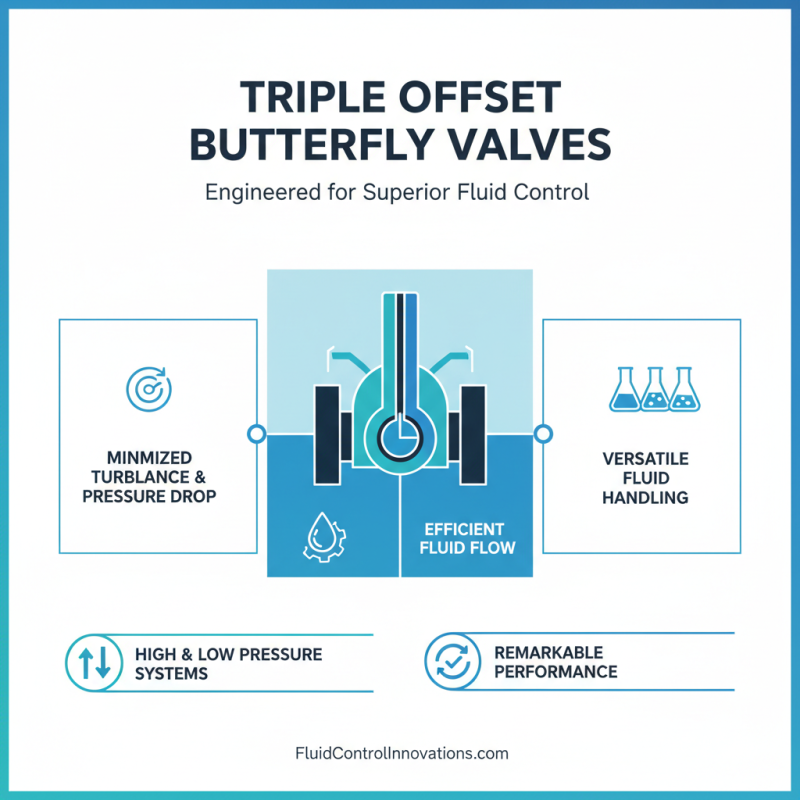

Enhanced Performance Characteristics in Fluid Control

Triple offset butterfly valves offer remarkable performance characteristics in fluid control applications. Their unique design minimizes turbulence and pressure drop. This ensures a more efficient fluid flow. The ability to handle various fluids makes these valves highly versatile. In addition, they are effective for both high and low-pressure systems.

The sealing mechanism is another advantage worth noting. It provides a tight shut-off, which reduces leaks significantly. This can lead to cost savings in maintenance and energy. Operators appreciate the ease of installation, which simplifies project planning. However, it’s essential to remember that proper alignment is crucial during installation. Misalignment can lead to performance issues.

While these valves excel in many situations, they may not be suitable for every application. User experience can vary based on specific project needs. Sometimes, additional considerations are required for extreme temperatures or chemical exposure. Regular maintenance is still necessary to ensure optimal performance. Reflecting on these aspects allows for better decision-making. Choosing the right valve impacts the overall efficiency of fluid systems.

Advantages in Energy Efficiency and Cost Savings

Triple offset butterfly valves are becoming increasingly popular in various projects due to their significant advantages in energy efficiency and cost savings. According to industry reports, these valves can enhance energy efficiency by up to 30%. This reduction often translates into substantial savings over time. For facilities aiming to lower their operational costs, switching to these valves is a strategic move.

One notable feature is their ability to create a tight seal, minimizing leakage. This can lead to reduced energy losses during operation. A tight seal also means less wear and tear, which can decrease maintenance costs by up to 20%. This is particularly beneficial for industries dealing with high-pressure systems.

Another consideration is the impact on system performance. While these valves are efficient, there can be challenges in retrofitting existing systems. Proper evaluation is crucial to avoid unforeseen costs. Aim to work with engineers familiar with the technology to minimize potential pitfalls during installation.

Applications and Use Cases for Triple Offset Butterfly Valves

Triple offset butterfly valves are gaining popularity in various industries. Their design allows for excellent sealing and durability. They work well in applications ranging from water treatment to chemical processing. These valves ensure minimal leakage, which is crucial in sensitive environments. With their unique geometry, they can handle high-pressure and temperature variations.

Applications of triple offset butterfly valves include oil and gas pipelines. They are also used in HVAC systems for their efficiency. In the food and beverage sector, these valves maintain hygiene standards. They can easily be integrated into existing systems without extensive modifications. However, installation sometimes poses challenges. Operators must ensure proper alignment and support to avoid issues down the line.

The versatility of these valves makes them suitable for both industrial and municipal applications. While they offer many benefits, users must remain vigilant about maintenance. Regular inspections can prevent costly failures. Proper training for operators is necessary to maximize their potential. These valves serve well, but any oversight may lead to inefficiencies that should be addressed.

Long-term Durability and Maintenance Benefits

Triple offset butterfly valves offer remarkable long-term durability. Their unique design minimizes wear and tear. This leads to fewer replacements over time. A durable valve can withstand various conditions, including high pressure and temperature. Engineers often appreciate this reliability in demanding environments.

Maintenance is another critical aspect. These valves require less frequent servicing, saving time and money. When they do need attention, access points are convenient. However, some users might find the maintenance instructions tricky. It requires careful reading and understanding.

The material used in construction plays a significant role. Quality materials resist corrosion and erosion. However, not all materials perform equally in every environment. Organizing routine checks can help identify potential issues early. Even with strong designs, neglect can lead to problems. Regular inspection ensures the system runs smoothly over time.

Related Posts

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

How to Choose the Right Cast Iron Butterfly Valve for Your Industrial Needs

-

Top 10 Benefits of Using Triple Offset Butterfly Valves in Industrial Applications

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications