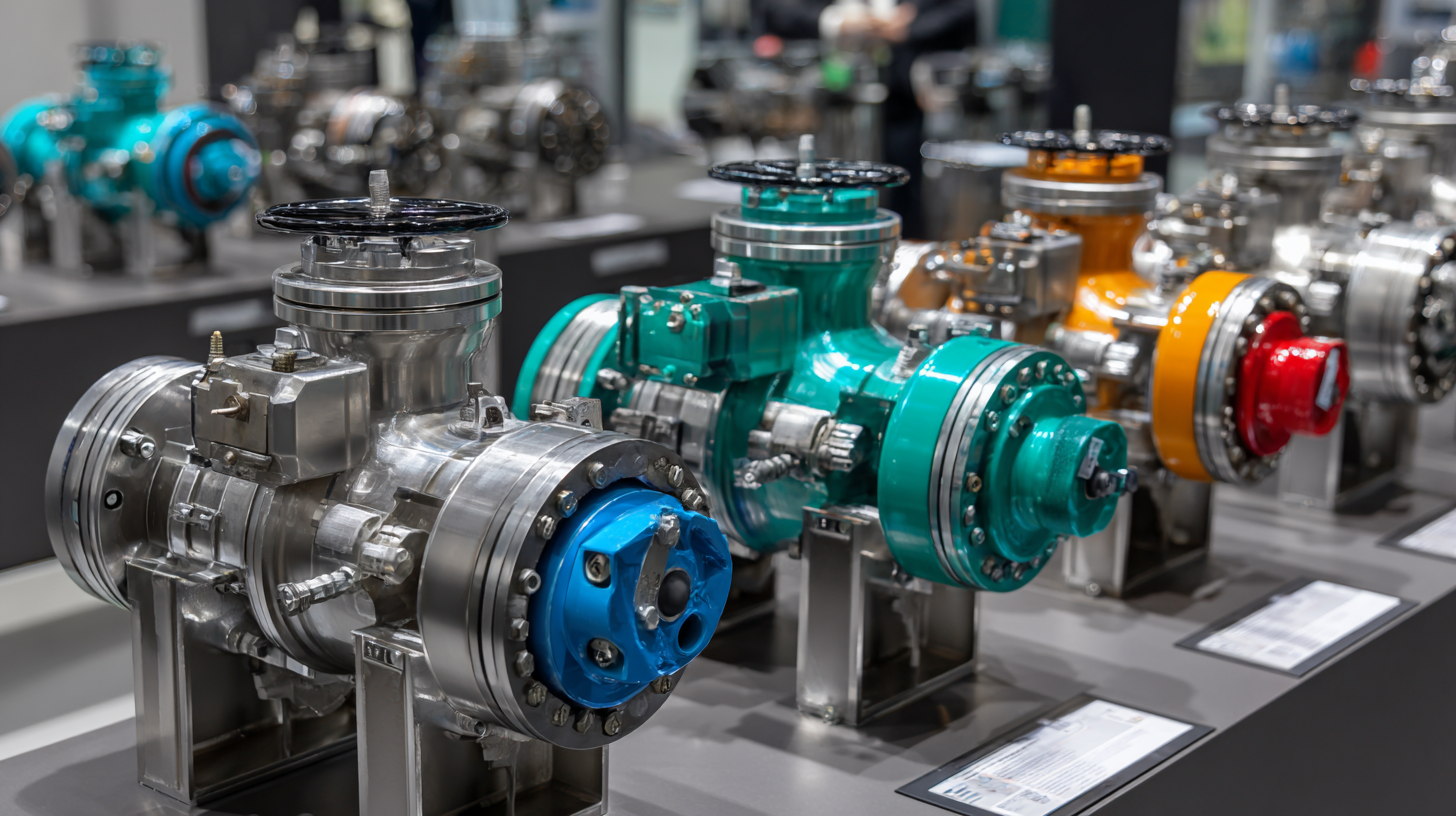

Emerging Trends in Butterfly Valves Industry Exhibited at China Import and Export Fair 2025

The butterfly valves industry is witnessing significant advancements and innovations, as demonstrated at the 138th China Import and Export Fair in 2025. With the global butterfly valves market projected to reach approximately $7 billion by 2026, growing at a CAGR of 5% from 2021, the fair spotlighted key emerging trends in this sector. Key players are increasingly focusing on the development of smart and automated butterfly valves, driven by the rising demand for efficient fluid control in various applications, including water treatment, oil and gas, and HVAC systems. Notably, China's burgeoning infrastructure projects and industrial growth contribute to the increasing consumption of butterfly valves, underscoring the importance of this event in showcasing cutting-edge solutions and promoting collaboration among industry stakeholders. As the market evolves, the insights gained from the fair will play a crucial role in shaping the future landscape of butterfly valves, ensuring they meet the diverse needs of industries worldwide.

Emerging Technologies Transforming Butterfly Valve Manufacturing Process

The butterfly valve industry is undergoing a significant transformation thanks to the emergence of advanced technologies that are reshaping manufacturing processes. According to a recent report by ResearchAndMarkets, the global butterfly valve market is projected to reach USD 10.89 billion by 2026, growing at a CAGR of 6.25% from 2021 to 2026. This growth is largely attributed to the adoption of automated systems and smart technologies that enhance production efficiency and accuracy.

The butterfly valve industry is undergoing a significant transformation thanks to the emergence of advanced technologies that are reshaping manufacturing processes. According to a recent report by ResearchAndMarkets, the global butterfly valve market is projected to reach USD 10.89 billion by 2026, growing at a CAGR of 6.25% from 2021 to 2026. This growth is largely attributed to the adoption of automated systems and smart technologies that enhance production efficiency and accuracy.

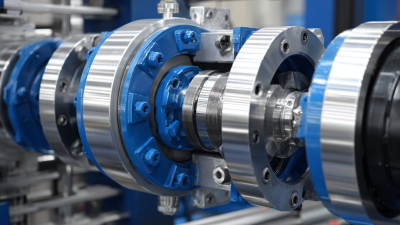

One of the major trends observed at the China Import and Export Fair 2025 is the integration of Industry 4.0 technologies in butterfly valve manufacturing. Automation and data exchange in manufacturing technologies have led to the implementation of IoT-enabled devices that monitor performance in real-time, reducing downtime and maintenance costs. Furthermore, innovative materials and 3D printing techniques are being utilized to produce lightweight and corrosion-resistant valves, which are critical for various applications including water treatment and chemical processing.

Moreover, advancements in simulation software allow manufacturers to design, analyze, and optimize valve performance before the production phase. This not only speeds up the development cycle but also minimizes material waste. As manufacturers embrace these emerging technologies, the butterfly valve industry is poised to enhance its operational capabilities and meet the increasing demands for efficiency and sustainability in various sectors.

Market Analysis of Butterfly Valves: Growth Trends and Key Players in 2025

The Hygienic Pumps and Valves market is currently on an upward trajectory, driven by increased demand across various industries such as food and beverage, pharmaceuticals, and biotechnology. As hygiene standards become more stringent, the need for reliable and efficient pumping and valve solutions has gained substantial attention. Market players are focusing on innovation and compliance with international standards to cater to this growing demand, which is reflected in their investments in advanced technologies and materials.

In 2025, the butterfly valves sector is expected to see significant advancements, revealing key trends in the market. The integration of smart technologies and automation in valve systems is transforming how industries operate, enhancing efficiency, and reducing downtime. Major players are leveraging these trends to improve their product offerings, positioning themselves to capture a larger share of the market. The competitive landscape is also intensifying, with emerging companies challenging established players by introducing innovative solutions that meet specific customer needs in hygienic applications.

Emerging Trends in Butterfly Valves Industry Exhibited at China Import and Export Fair 2025

| Dimension | 2025 Value | Growth Rate (%) | Market Share (%) |

|---|---|---|---|

| Market Size (Million $) | $2,000 | 5.5 | 20 |

| Production Volume (Units) | 1,500,000 | 4.2 | 23 |

| Export Volume (Units) | 300,000 | 6.0 | 15 |

| Leading Region (% Share) | Asia Pacific | 7.0 | 30 |

Impact of Sustainability and Eco-friendly Materials on Butterfly Valve Design

The emerging trends in the butterfly valve industry, highlighted at the 2025 China Import and Export Fair, reveal a growing emphasis on sustainability and the use of eco-friendly materials in product design. According to a recent report by MarketsandMarkets, the butterfly valve market is projected to reach $7.5 billion by 2026, with a significant shift towards greener solutions. This trend is largely driven by increasing environmental regulations and the demand for energy-efficient systems across various sectors, including water treatment, oil and gas, and power generation.

Manufacturers are responding to this demand by innovating with materials such as recycled plastics and biocomposites, which not only reduce the carbon footprint but also enhance the durability and performance of butterfly valves. For instance, a study by Grand View Research indicates that the adoption of sustainable materials in valve manufacturing can lead to a reduction in greenhouse gas emissions by up to 30%. As the industry continues to evolve, the incorporation of sustainability into butterfly valve design not only aligns with global environmental efforts but also caters to the expectations of environmentally-conscious consumers and businesses alike.

Customer Preferences Shaping the Future of Butterfly Valve Applications

The butterfly valve industry is witnessing significant transformations as customer preferences increasingly dictate the direction of product innovation and application. At the 2025 China Import and Export Fair, manufacturers showcased a variety of butterfly valves designed to meet the evolving needs of various sectors, including water management, chemical processing, and HVAC systems. Notably, there is a growing demand for valves that offer enhanced durability, efficiency, and ease of maintenance. This shift reflects a broader trend towards sustainability, with customers prioritizing products that contribute to energy savings and reduction of environmental impact.

Moreover, advancements in technology have allowed for greater customization of butterfly valves. Many customers now seek solutions tailored to their specific operational requirements, with features such as intelligent monitoring systems and remote control capabilities becoming increasingly popular. This trend underscores a need for manufacturers to engage directly with consumers to better understand their challenges and preferences, ensuring that future developments are aligned with market demands. The integration of customer feedback into design processes is not only enhancing the functionality of butterfly valves but is also fostering stronger relationships between producers and end-users in this competitive industry.

Emerging Trends in Butterfly Valves Industry - Customer Preferences

Innovations in Automation Enhancing Butterfly Valve Performance and Efficiency

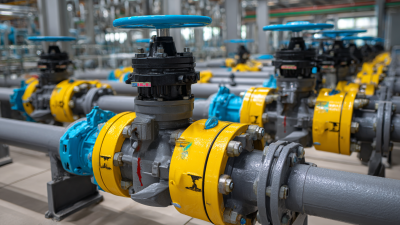

At the China Import and Export Fair 2025, the spotlight was on a wave of innovations driving advancements in the butterfly valve industry, particularly through automation. As industries strive for greater efficiency and reduced operational costs, the integration of smart technologies in butterfly valve design is becoming paramount. Automated butterfly valves equipped with advanced sensors and AI-driven control systems not only facilitate precise flow management but also enhance energy efficiency, thereby reducing overall emissions.

Companies showcased cutting-edge solutions that highlight the synergy between automation and valve performance. For instance, real-time monitoring capabilities enable predictive maintenance, minimizing downtime and resource wastage. The incorporation of IoT technology allows for seamless integration into larger automated systems, providing operators with valuable insights and facilitating quick adjustments based on operational demands. This trend towards smarter, automated butterfly valves is not only transforming manufacturing processes but also setting new benchmarks in performance and reliability across various sectors.

Related Posts

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

Unlocking Performance with Best Stainless Steel Valves Comprehensive Technical Parameters and How to Choose the Right Fit

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

5 Reasons Why Actuated Butterfly Valves Are the Best Choice for Efficient Flow Control

-

How to Select the Best Actuated Butterfly Valve for Optimal Process Efficiency in Global Industries