Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications

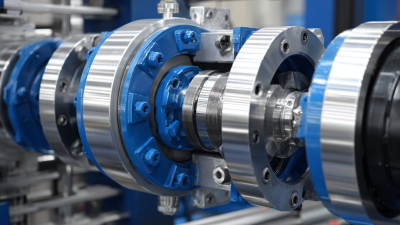

In the realm of industrial applications, the cast iron butterfly valve has emerged as a crucial component in fluid control systems, revered for its durability and efficiency. According to a recent market research report by Grand View Research, the global butterfly valve market is projected to reach $5.3 billion by 2025, with cast iron variants gaining significant traction due to their superior performance in high-pressure environments. These valves are particularly favored in sectors such as water treatment, oil and gas, and chemical processing, where reliability is paramount.

Cast iron butterfly valves offer distinct advantages, including lower maintenance costs and ease of operation, making them an ideal choice for various industrial processes. As industries continue to evolve, understanding the different types of cast iron butterfly valves and their specific applications will be essential for optimizing performance and enhancing operational efficiency.

Types of Cast Iron Butterfly Valves: An Overview of Common Designs

Cast iron butterfly valves are essential components in various industrial applications, renowned for their durability and efficiency. This blog delves into the common designs of these valves, which are integral to managing flow in pipelines and processes. Among the popular types are the concentric, eccentric, and double eccentric designs. The concentric butterfly valves are typically used in low-pressure systems, while eccentric designs, including high-performance variants, are ideal for applications requiring tight sealing and robust functionality under varying conditions. According to a recent market analysis, the demand for these valves is projected to grow by 5% annually, driven by advancements in manufacturing and increasing industrial automation.

When selecting a cast iron butterfly valve, it’s essential to consider application specifics such as the nature of the fluid and pressure conditions. Always ensure that the valve's design matches your system requirements to maximize efficiency and prevent leaks.

Tip: Regular maintenance and inspection can significantly extend the life of your butterfly valves. Implementing a scheduled maintenance program can help identify potential issues before they escalate, reducing downtime and operational costs.

Key Features and Benefits of Cast Iron Butterfly Valves in Industrial Use

Cast iron butterfly valves are integral to seamless operation in various industrial applications. One of their key features is the ability to provide a tight seal, minimizing leakage in fluid systems. According to a report by the MarketsandMarkets research group, the global butterfly valve market is expected to grow from $6.4 billion in 2021 to $8.3 billion by 2026, driven largely by increased demand in the oil and gas, water treatment, and chemical industries. This growth is attributed to the durability and reliability of cast iron valves under high-pressure conditions.

Another significant benefit of using cast iron butterfly valves is their lightweight nature compared to traditional gate or globe valves, allowing for easier installation and maintenance. In addition, they exhibit excellent resistance to corrosion and wear, making them suitable for handling abrasive slurries and corrosive fluids. According to the American Society of Mechanical Engineers (ASME), the thermal conductivity of cast iron contributes to temperature stability, maintaining performance in extreme conditions. This versatility proves essential in environments where maintaining precise flow control is crucial to operational efficiency.

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications

| Valve Type | Size Range (inches) | Pressure Rating (psi) | Temperature Range (°F) | Applications | Benefits |

|---|---|---|---|---|---|

| Lug Type | 2 - 12 | 150 | -20 to 200 | Water Treatment, HVAC | Cost-effective, Compact design |

| Wafer Type | 3 - 16 | 200 | -10 to 250 | Chemical Processing, Food Industry | Lightweight, Versatile |

| Double Flanged | 4 - 24 | 250 | -30 to 300 | Oil & Gas, Power Generation | Robust, High performance |

| Centerline Type | 6 - 30 | 300 | -20 to 400 | Mining, Water Distribution | Durable, Easy maintenance |

Selecting the Right Cast Iron Butterfly Valve for Specific Applications

When selecting the right cast iron butterfly valve for specific applications, it is essential to consider factors such as pressure rating, temperature tolerance, and chemical compatibility. According to a recent market analysis by Research and Markets, the global butterfly valve market is projected to reach USD 4.26 billion by 2027, reflecting a growing demand in industrial sectors such as water treatment, oil, and gas. This indicates a significant reliance on effective valve solutions, prompting engineers to choose the right type based on operational parameters.

For instance, in high-pressure environments, a cast iron butterfly valve with enhanced sealing capabilities and a higher pressure rating becomes imperative. Similarly, for applications that involve corrosive substances, epoxy-coated cast iron valves provide increased resistance, thus extending their service life. Data from the American National Standards Institute (ANSI) suggests that choosing the appropriate valve type can enhance operational efficiency by up to 30%. Understanding the nuances of each type of cast iron butterfly valve, including their designs and materials, can lead to more informed decisions that optimize performance and reliability in industrial applications.

Maintenance Tips for Ensuring Longevity of Cast Iron Butterfly Valves

When it comes to maintaining cast iron butterfly valves in industrial applications, proper care and attention can significantly enhance their longevity and performance. Regular inspection is crucial; operators should check for any signs of wear or corrosion, especially in the valve seats and sealing edges. A systematic approach to maintenance, which includes cleaning and lubricating moving parts, will help ensure smooth operation. Additionally, ensuring that the valves are properly aligned and not subjected to undue stress can prevent premature failure.

Another vital aspect of maintenance is monitoring the operating conditions. It’s essential to keep the valves within their specified pressure and temperature limits to avoid excessive wear. Operators should also be vigilant about the media flowing through the valve; abrasive or corrosive substances can drastically reduce the lifespan of cast iron components. Employing appropriate protective coatings or liners can mitigate these risks. Lastly, establishing a routine schedule for maintenance checks can help catch potential issues early, allowing for timely repairs and reducing unexpected downtime in industrial processes.

Comparative Analysis: Cast Iron Butterfly Valves vs. Other Valve Materials

When selecting valves for industrial applications, the choice of material is crucial to ensure performance and reliability.

Cast iron butterfly valves have become a popular option due to their robust construction and versatility.

According to a recent report from the American Society of Mechanical Engineers (ASME),

cast iron valves can withstand pressures of up to 250 psi, making them suitable for a wide range of liquid and gas control applications.

In contrast to other materials like stainless steel and PVC, cast iron offers a unique balance of cost-effectiveness and durability.

A study by the International Valve Manufacturer Association (IVMA) found that while

stainless steel valves may provide superior corrosion resistance and longevity, their initial investment can be up to 40% higher than that of cast iron.

Conversely, PVC valves, while lightweight and resistant to certain chemicals, may lack the strength required for high-pressure systems.

Thus, for industries where budget constraints are paramount without compromising on quality,

cast iron butterfly valves present a compelling alternative that combines affordability with reliability in demanding environments.

Related Posts

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

Unlocking Performance with Best Stainless Steel Valves Comprehensive Technical Parameters and How to Choose the Right Fit

-

Essential Control Valves Maintenance Checklist for Optimal Performance

-

Ultimate Guide to Choosing the Right Electric Valves for Your Industrial Needs

-

Common Issues Faced by Gate Valves in High Pressure Applications