How to Choose the Right Actuated Valves for Your System?

Choosing the right actuated valves for your system can significantly impact performance. According to a report by MarketsandMarkets, the actuated valve market is projected to reach $12.91 billion by 2025. This growth reflects the increasing demand for automation in various industries.

Expert John Smith, a leading figure in valve technology, emphasizes, "Selecting the right actuated valves is crucial for operational efficiency." When faced with numerous options, it’s essential to consider several factors. These include fluid type, pressure, and temperature. Each characteristic influences valve performance.

Often, engineers overlook the importance of compatibility. It can lead to costly mistakes and downtime. Making an informed choice requires understanding the nuances of both the application and the valve itself. Choosing actuated valves is not just about functionality; it involves a careful analysis of your specific needs and constraints.

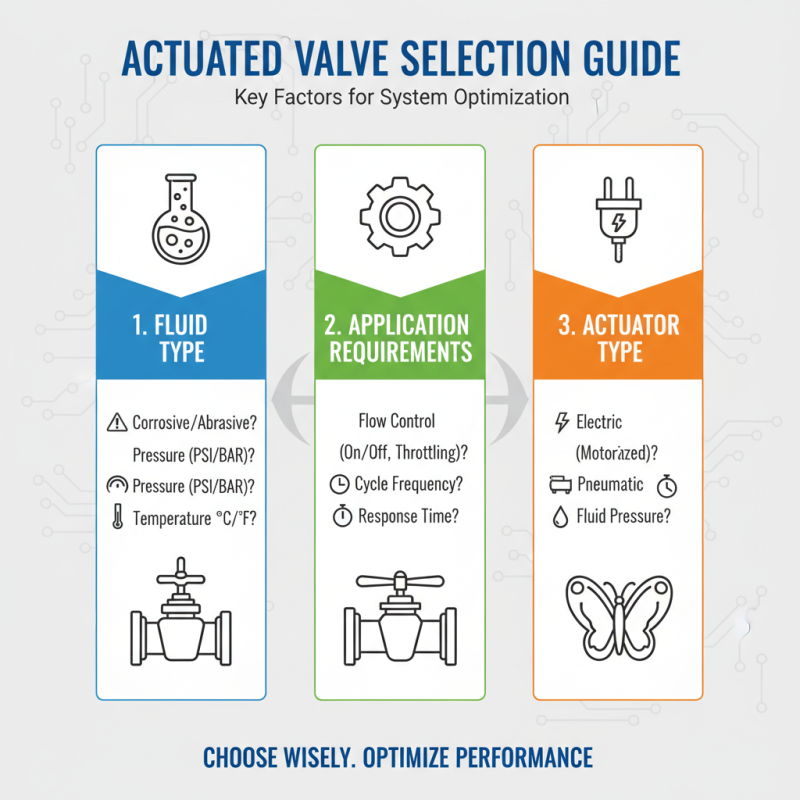

Factors to Consider When Selecting Actuated Valves for Your System

Choosing the right actuated valves for your system requires careful consideration of several key factors. Begin by assessing the fluid type. Different fluids exert varying pressures and temperatures that affect valve performance. For instance, corrosive fluids may require special materials. Standard valves might not handle these well, leading to failures.

Another important aspect is the application pressure range. Valves must operate consistently within specified pressure limits. Too high or too low could cause inefficiencies. Additionally, actuator type plays a crucial role. Electric actuators offer precision but may require more maintenance than pneumatic ones. It's vital to reflect on your system's needs and limitations.

Also, don’t overlook the size of the valve. A valve that is too small can create flow restrictions. Yet, one that is oversized might lead to turbulence and inefficiency. Users often underestimate these effects. Take time to measure and calculate accurately. Each choice has consequences. Ignoring them could lead to performance issues.

Understanding Different Types of Actuated Valves and Their Applications

Actuated valves play a crucial role in various industries. Their applications can range from controlling flow in water systems to regulating gases in chemical processes. Understanding the different types of actuated valves is essential when selecting the right one for your system.

Electric actuated valves are popular due to their precision. They provide quick and reliable control. However, they may not work well in extreme environments. Pneumatic actuated valves are another option. They offer fast operation and can handle high pressures. Yet, these valves require a compressed air source, which isn’t always available.

Hydraulic actuated valves can manage heavy-duty applications. They are robust but can be more complex to operate. Consider the environment and specific needs of your system. It's easy to overlook the potential limitations of each valve type. Choosing the right valve often requires careful evaluation of application requirements and system constraints.

Actuated Valves Types and Applications

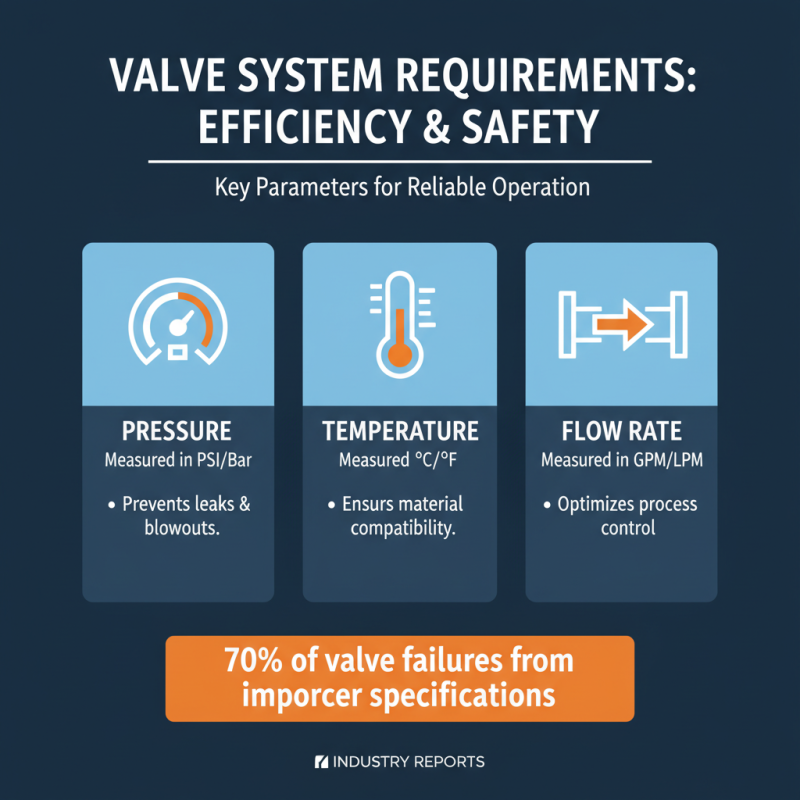

Evaluating System Requirements: Pressure, Temperature, and Flow Rate

Choosing the right actuated valves hinges on understanding key system requirements: pressure, temperature, and flow rate. Each of these factors plays a crucial role in ensuring efficiency and safety. According to industry reports, around 70% of valve failures stem from improper specifications related to these parameters.

Pressure ratings are vital. Systems operate within a specific pressure range. Exceeding this can lead to valve malfunctions. Many valves are rated by their maximum allowable pressure, often specified in pounds per square inch (psi). Knowing your system's peak pressure is critical. If you underestimate, the consequences can be significant.

Temperature also influences valve function. High temperatures can deform materials, while low temperatures may lead to brittleness. Most actuated valves have a rated temperature range. It’s essential to match the valve with your system’s temperature conditions. Reports indicate that about 25% of installations face issues due to temperature mismatches.

Flow rate is another essential aspect. The flow characteristics determine the size and type of the valve. Too small a valve restricts flow; too large results in inefficiency. Conducting a flow analysis can provide insights into the required specifications.

Tips: Always consult the performance curves of the valves. They provide critical data on pressure drops and flow coefficients. Consider performance under varying conditions to avoid pitfalls. Evaluate your installation regularly. This can help identify potential issues before they escalate.

Key Industries Using Actuated Valves and Their Specific Needs

Actuated valves play a critical role in various industries. Each sector has distinct needs that require careful consideration. For example, the oil and gas industry often requires valves that handle high pressures and temperatures. According to a report by Markets and Markets, the global actuated valves market is projected to reach $4.9 billion by 2025. This highlights the growing demand for reliable and efficient systems in this sector.

In the water treatment industry, actuated valves need to manage corrosive environments. They must ensure safety and efficiency in processing water. Research by Research and Markets indicates that water treatment facilities hold a significant share of the valve market. Economic factors also drive innovation. Valves that can minimize energy consumption are increasingly preferred.

The chemical industry emphasizes the need for precise control. Actuated valves must support a range of harsh chemicals. Improved designs can reduce leakage and downtime. Despite advancements, challenges remain. Many facilities struggle with selecting the right actuated valves. Some do not consider long-term maintenance costs. Understanding the specific needs of each industry is vital for enhancing system performance.

How to Choose the Right Actuated Valves for Your System? - Key Industries Using Actuated Valves and Their Specific Needs

| Industry | Specific Needs | Common Actuated Valve Types | Typical Applications |

|---|---|---|---|

| Oil & Gas | High pressure and temperature resistance | Ball Valves, Gate Valves | Pipeline control, safety systems |

| Water Treatment | Corrosion resistance and flow regulation | Globe Valves, Butterfly Valves | Chemical dosing, filtration control |

| Pharmaceuticals | Sanitary design and precision control | Diaphragm Valves, Ball Valves | Process control, sterile applications |

| Food & Beverage | Hygienic design and easy cleaning | Butterfly Valves, Check Valves | Fluid transfer, mixing processes |

| HVAC | Energy efficiency and balance | Electric Actuated Ball Valves, Control Valves | Temperature control, air handling units |

Future Trends in Actuated Valve Technology and Automation Insights

The future of actuated valve technology is evolving rapidly. Automation plays a significant role in this transformation. Smart actuated valves are becoming essential in many systems. These valves can self-diagnose issues and offer real-time data. This allows operators to make informed decisions quickly. Data analytics enhances efficiency and reduces downtime.

Integration with IoT is another critical trend. Actuated valves can communicate with other devices seamlessly. This connectivity enables remote monitoring and control. However, security remains a concern. Vulnerabilities in the system may expose critical data. Balancing automation and safety requires careful consideration.

New materials are also changing valve design. Lightweight and corrosion-resistant materials are emerging. This evolution leads to longer life cycles and reduced maintenance. Yet, not all industries are adopting these innovations. Some processes still rely on older technology. This gap needs addressing as industries strive for progress. Embracing change is challenging, but it’s vital for future success.

Related Posts

-

Ultimate Guide to Choosing the Right Electric Valves for Your Industrial Needs

-

Top 10 Benefits of Using Triple Offset Butterfly Valves in Industrial Applications

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

How to Choose the Right Industrial Valves for Your Needs?

-

Top 10 Benefits of Using Actuated Butterfly Valves in Industrial Applications

-

Why Electric Valves are Essential for Efficient Fluid Control Systems