10 Essential Tips for Choosing the Right Cast Iron Butterfly Valve for Your Pipeline Systems

In the ever-evolving landscape of pipeline systems, selecting the right component materials is crucial for ensuring durability and efficiency. Among these materials, the cast iron butterfly valve plays a vital role in regulating flow and pressure within various industrial applications. According to a recent market analysis by the Global Valves Industry Report 2023, the demand for cast iron butterfly valves has surged, projected to grow by 15% annually due to increasing investments in infrastructure and industrial upgrades. Expert Dr. Emily Sanders, a leading authority in fluid control systems, emphasizes, "The choice of butterfly valve can significantly impact the operational efficiency and maintenance costs of pipeline systems."

As the industry progresses towards more advanced and sustainable practices, the selection process for cast iron butterfly valves requires a strategic approach. With multiple designs and specifications available, it is essential to evaluate key factors such as material compatibility, pressure ratings, and environmental conditions. Research from the Pipeline Infrastructure Alliance highlights that improper valve selection can lead to up to a 25% increase in maintenance expenditures, underscoring the importance of informed decision-making. These tips aim to guide engineers and procurement professionals in navigating the complexities of selecting the ideal cast iron butterfly valve, ensuring optimal performance in their pipeline systems.

Understanding Pipe System Requirements Before Selecting a Cast Iron Butterfly Valve

Before choosing a cast iron butterfly valve for your pipeline systems, it is crucial to fully understand the requirements of your specific pipe system. Each pipeline has unique characteristics, including fluid type, pressure, and temperature, which dictate the valve’s suitability and performance. For instance, a valve that performs well in a low-pressure water system may not withstand the rigors of a high-pressure gas line. Analyzing these parameters will ensure that the selected valve not only fits within the engineering specifications but also operates efficiently throughout its lifespan.

Additionally, consider the flow characteristics and the intended application of the butterfly valve. Different systems may require varying degrees of control and flow regulation, influencing the design and functionality of the valve. It is also important to assess the installation environment—corrosive or high-temperature conditions may warrant specific materials or protective coatings on the valve. By meticulously evaluating these factors, you can choose a cast iron butterfly valve that will enhance the overall reliability and efficiency of your pipeline systems while minimizing maintenance and operational issues.

10 Essential Tips for Choosing the Right Cast Iron Butterfly Valve for Your Pipeline Systems

| Tip | Description | Considerations |

|---|---|---|

| 1. Understand Your Pipeline Requirements | Evaluate the specific needs of your pipeline system. | Fluid type, pressure, and temperature. |

| 2. Determine Valve Size | Select the right diameter based on flow requirements. | Refer to flow rate and pipe size charts. |

| 3. Choose the Right Material | Material should withstand operational conditions. | Consider corrosion resistance and temperature limits. |

| 4. Inspect Valve Design | Review design factors affecting flow and sealing. | Look for designs that minimize turbulence. |

| 5. Evaluate Actuation Options | Consider manual vs automated operation mode. | Identify need for power supply and control systems. |

| 6. Check for Certifications and Standards | Ensure compliance with industry standards. | Look for ANSI, API, or ISO certifications. |

| 7. Analyze Pressure and Temperature Ratings | Ensure valve can handle system pressure and temperature. | Check valve specifications carefully. |

| 8. Consider Maintenance Requirements | Assess ease of maintenance and replacement parts. | Investigate support and service from suppliers. |

| 9. Budget for Total Cost | Factor in installation, maintenance, and operational costs. | Don't just consider the initial purchase price. |

| 10. Consult with Experts | Seek advice from industry professionals when in doubt. | Use insights from experienced engineers and technicians. |

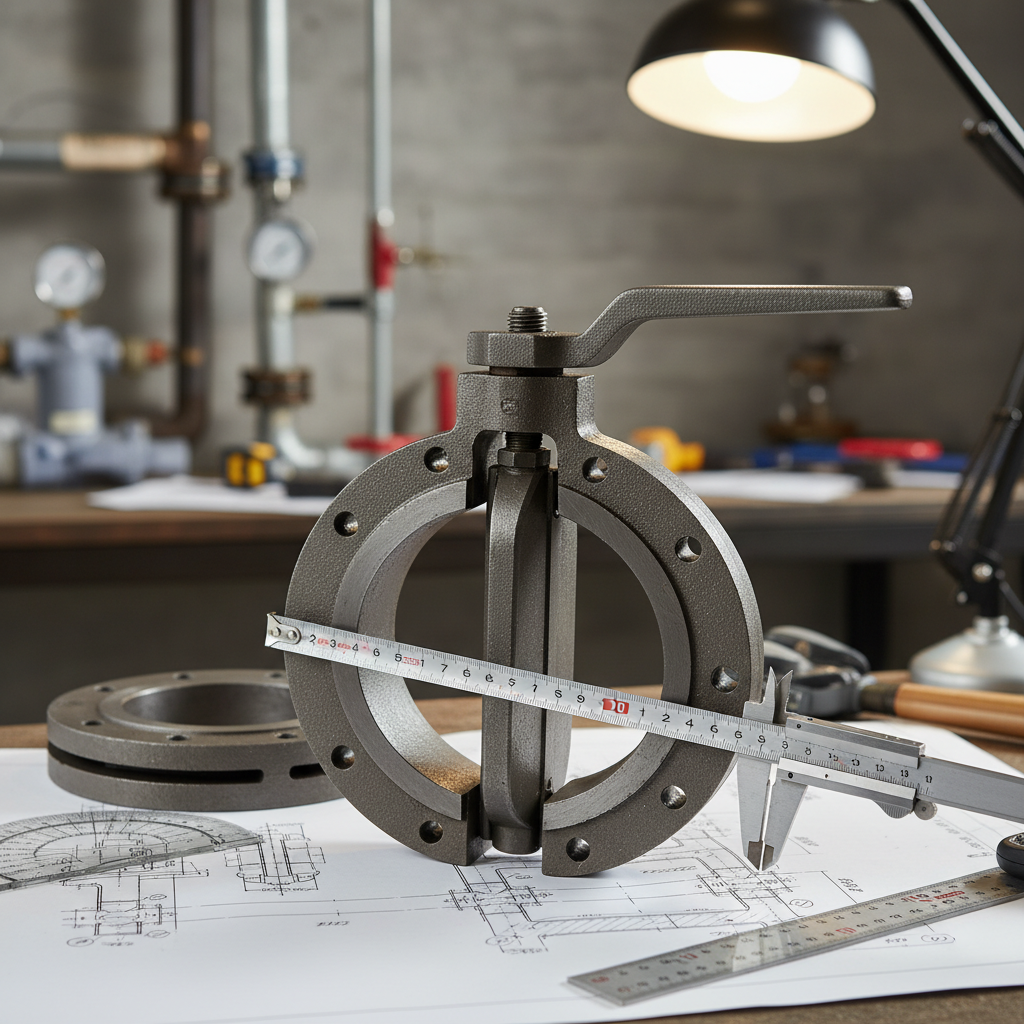

Evaluating Size and Dimensions for Optimal Flow Control in Pipeline Systems

When selecting the right cast iron butterfly valve for your pipeline systems, understanding the size and dimensions is crucial for achieving optimal flow control. The diameter of the valve should match the existing pipeline to prevent bottlenecks or excessive turbulence, which can compromise efficiency. Additionally, consider the overall dimensions, including the face-to-face length, which affects space requirements for installation and maintenance.

One essential tip is to assess the flow characteristics of your system. This involves calculating the expected flow rate and pressure drops throughout the system, enabling you to choose a butterfly valve that can handle those conditions without losing performance. Another important factor is to ensure that the valve's actuator type and size are compatible with the selected valve dimensions, allowing for smooth operation and quick response times.

It’s also helpful to evaluate the environment where the butterfly valve will be installed. Factors such as temperature, chemical exposure, and surrounding conditions can influence the valve’s performance and longevity. This insight will guide you in selecting a valve with the right materials and design features for durability and reliability in your pipeline system.

Material Composition: Ensuring Durability in High-Pressure and Corrosive Environments

When selecting a cast iron butterfly valve, the material composition is paramount, especially for applications in high-pressure and corrosive environments. Cast iron is a popular choice due to its durability and resistance to wear. However, it's crucial to ensure that the specific type of cast iron used is suited to the operational conditions. Look for valves made from ductile iron or those that feature protective coatings, as these can enhance corrosion resistance and ensure longevity.

One essential tip is to evaluate the valve's construction and whether it includes additional features such as reinforced seats or specialized gaskets designed for harsh conditions. Additionally, consider the temperature and pressure ratings of the valve; ensure they align with your system's requirements to prevent potential failures. Regular maintenance is another key aspect; choose a valve that allows easy access for inspection and servicing to ensure it performs reliably over time. By focusing on these aspects of material composition, you can significantly enhance the durability and functionality of your pipeline systems.

Material Composition Analysis of Cast Iron Butterfly Valves

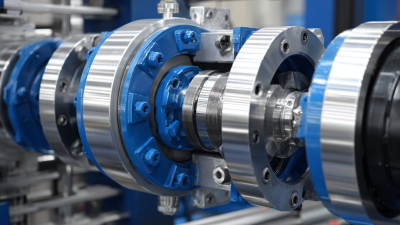

Assessing Valve Actuation Mechanisms for Efficient Pipeline Operations

When selecting a cast iron butterfly valve for your pipeline systems, understanding the valve actuation mechanism is crucial for maintaining efficient operations. Actuation options can range from manual to automatic, each with its benefits tailored to specific operational needs. For instance, pneumatic or electric actuators can enhance responsiveness in larger systems, while manual actuators remain suitable for smaller, less complex setups.

Carefully consider the environment in which the valve will operate, as factors such as temperature and exposure to corrosive substances can influence actuator performance and longevity.

To prevent corrosion in pipelines, it is vital to implement best practices that ensure the integrity of both the system and its components. Regular inspections and maintenance should be conducted to identify early signs of wear or damage. Additionally, applying protective coatings and using corrosion-resistant materials can dramatically reduce the likelihood of degradation over time.

Employing corrosion inhibitors in the fluid can also provide an extra layer of protection, further enhancing the lifespan of your pipeline systems. Remember that choosing the appropriate valve with a suitable actuation mechanism plays a significant role in the overall efficiency and maintenance of your pipeline operations.

Comparing Cost and Quality: Finding Value in Your Butterfly Valve Investment

When investing in a cast iron butterfly valve for your pipeline systems, understanding the balance between cost and quality is essential. A lower price may seem attractive, but it often compromises the durability and performance that you rely on. Therefore, consider the long-term value of your investment. Look for manufacturers with a reputation for producing high-quality products, as well as those who offer warranties or guarantees. This can provide peace of mind that your valve will stand the test of time.

One critical tip is to evaluate the materials used in the valve construction. High-quality cast iron can significantly enhance durability and resistance to wear and corrosion. Additionally, assess the valve's design features, such as the seat type and disc material, which can impact the overall performance. Investing in a well-designed valve can lead to lower maintenance costs and fewer operational disruptions.

Another important factor to consider is the compatibility of the butterfly valve with your specific pipeline system. Ensure that the size, pressure ratings, and connection types match your existing setup. Conduct thorough research or consult with industry experts to help identify the best fit for your needs, allowing you to achieve optimal efficiency without over-investing.

Related Posts

-

How to Choose the Right Cast Iron Butterfly Valve for Your Industrial Needs

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

10 Best Triple Offset Butterfly Valves for Enhanced Efficiency and Durability

-

Understanding the Future of Automated Valves in Modern Industry Technology