How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

In today's competitive industrial landscape, optimizing pipeline efficiency is crucial for both operational effectiveness and cost management. One effective solution gaining traction in the UK is the use of butterfly valves, known for their ability to offer quick and reliable flow regulation. According to a recent report by MarketsandMarkets, the global butterfly valve market is projected to reach USD 10.68 billion by 2025, with the UK accounting for a significant share due to its robust manufacturing and oil & gas sectors. The inherent design of butterfly valves allows for minimal pressure drop, which can lead to energy savings of approximately 15-20% in fluid transport systems. By understanding these advantages and integrating butterfly valves UK into their pipeline systems, companies can significantly enhance their efficiency, reduce operational costs, and align with sustainability goals.

Understanding Butterfly Valves: Types and Applications in Pipeline Systems

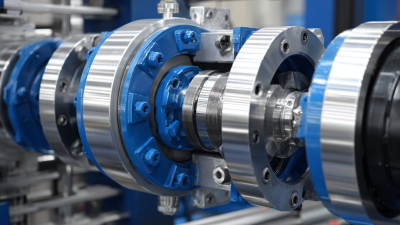

Butterfly valves are critical components in pipeline systems, renowned for their ability to regulate flow with minimal pressure loss. Available in various types, such as concentric, eccentric, and high-performance butterfly valves, each design caters to specific applications. Concentric butterfly valves are commonly used for general applications due to their simple design and cost-effectiveness. Eccentric types, on the other hand, are preferred in scenarios where tight sealing and high-pressure applications are required, as they enhance performance and longevity by reducing wear on the seat.

Recent industry reports highlight that the UK butterfly valve market is projected to grow at a CAGR of 5.6% from 2023 to 2030, driven by increasing demand in the oil and gas, water treatment, and chemical processing sectors. For instance, the latest data from the British Valve and Actuator Association indicates that butterfly valves account for nearly 25% of the total valve market, underscoring their importance in optimizing pipeline efficiency. Utilizing the appropriate type of butterfly valve based on specific system requirements can considerably enhance flow control, reduce maintenance costs, and improve overall system performance.

Key Benefits of Using Butterfly Valves for Enhanced Pipeline Efficiency

Butterfly valves are increasingly recognized for their ability to enhance pipeline efficiency, especially within the UK’s industrial sectors. One of the primary benefits of these valves is their compact design, which allows for significant space savings compared to traditional valve types. This feature not only reduces installation costs but also minimizes the overall footprint of the piping system, making it easier to integrate into existing infrastructures.

Butterfly valves are increasingly recognized for their ability to enhance pipeline efficiency, especially within the UK’s industrial sectors. One of the primary benefits of these valves is their compact design, which allows for significant space savings compared to traditional valve types. This feature not only reduces installation costs but also minimizes the overall footprint of the piping system, making it easier to integrate into existing infrastructures.

Another key advantage of butterfly valves is their quick operation. Unlike more complex valve systems that may require extensive manual effort or automation, butterfly valves can be opened or closed with a simple quarter turn. This swift action leads to faster flow control and reduces the potential for disruptions in fluid transport. Furthermore, the streamlined design of butterfly valves ensures minimal pressure loss, which translates to energy savings and improved efficiency throughout the pipeline system. As industries continue to seek ways to optimize operations, butterfly valves stand out as a practical and effective solution.

Best Practices for Installing Butterfly Valves in the UK Pipeline Networks

When installing butterfly valves in UK pipeline networks, adhering to best practices is crucial for optimizing efficiency and maintaining system integrity. According to a report by the British Valve and Actuator Association, improper installation can lead to significant pressure loss, with estimates suggesting that up to 30% of energy consumption in pipeline systems can be attributed to suboptimal valve performance. To mitigate this, ensuring that valves are installed in accordance with manufacturer specifications and industry standards can enhance flow characteristics and reduce maintenance costs.

Another key consideration is the positioning of butterfly valves within the pipeline. Industry best practices recommend placing valves at least five pipe diameters away from any elbow or bend to minimize turbulence and enhance flow stability. Additionally, utilizing a proper alignment and securing the valve with adequate supports can prevent operational issues. The UK’s Energy Institute has reported that following such guidelines can improve valve operational efficiency by approximately 15%, demonstrating the significant impact of careful installation on overall pipeline performance.

Pipeline Efficiency Optimization with Butterfly Valves in the UK

This chart illustrates the efficiency of pipeline flow rates when using butterfly valves in the UK. The data represents various flow categories and their corresponding efficiency percentages, highlighting optimal performance scenarios.

Monitoring and Maintenance: Ensuring Long-Term Performance of Butterfly Valves

Regular monitoring and maintenance are crucial to ensuring the long-term performance of butterfly valves, particularly in the UK’s diverse industrial sectors. According to a report by the British Valve and Actuator Association, approximately 30% of valve failures can be attributed to inadequate maintenance practices. Implementing a robust monitoring routine can significantly reduce these incidences, ensuring that butterfly valves operate efficiently and reliably, even in demanding environments.

Data from the UK’s Engineering and Physical Sciences Research Council highlights that predictive maintenance strategies, which include real-time monitoring, can improve valve lifespan by up to 40%. This approach allows companies to identify potential issues before they escalate, thus minimizing downtime and reducing the costs associated with emergency repairs. Moreover, utilizing advanced technologies such as IoT sensors for monitoring can provide valuable insights into valve performance, enabling prompt corrective actions that enhance overall pipeline efficiency and reliability.

Case Studies: Successful Pipeline Optimization with Butterfly Valves in the UK

In recent years, several case studies have highlighted the successful implementation of butterfly valves for optimizing pipeline efficiency across various sectors in the UK. For instance, a major water utility company undertook a project to replace traditional gate valves with advanced butterfly valves in its distribution network. This transition not only improved flow rates but also significantly reduced maintenance costs. The new design allowed for quicker operation and reduced water loss during valve manipulations, ultimately leading to enhanced service reliability for consumers.

Another notable case involved a natural gas pipeline where butterfly valves were employed to facilitate smoother operation in varying pressure conditions. Data from the project indicated a 20% increase in overall efficiency, primarily attributed to the valves' lightweight structure and quick response times. By using these valves, the company successfully minimized pressure drops and improved the safety and control of gas distribution. The measurable impacts from these case studies demonstrate the crucial role butterfly valves play in advancing pipeline efficiency, contributing to better resource management and operational sustainability.

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

| Case Study | Pipeline Diameter (mm) | Valve Type | Efficiency Improvement (%) | Energy Savings (kWh/year) |

|---|---|---|---|---|

| Case Study 1 | 300 | Double Offset | 15 | 3500 |

| Case Study 2 | 450 | Triple Offset | 20 | 5000 |

| Case Study 3 | 600 | Lugged | 25 | 8000 |

| Case Study 4 | 750 | Wafer Style | 18 | 6200 |

Related Posts

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

5 Essential Tips for Choosing the Right Cast Iron Butterfly Valve

-

Common Issues Faced by Gate Valves in High Pressure Applications

-

Understanding Pressure Valves and Their Impact on Industrial Safety

-

How to Select the Best Actuated Butterfly Valve for Optimal Process Efficiency in Global Industries