How to Optimize Your System Efficiency with Automated Valves

In an era where operational efficiency is paramount, the integration of automated valves is proving to be a game changer across various industries. According to a report by Grand View Research, the global market for automated valves is expected to reach $7.3 billion by 2025, growing at a CAGR of 6.0%. This growth reflects the increasing demand for precision control and enhanced reliability in process automation.

In an era where operational efficiency is paramount, the integration of automated valves is proving to be a game changer across various industries. According to a report by Grand View Research, the global market for automated valves is expected to reach $7.3 billion by 2025, growing at a CAGR of 6.0%. This growth reflects the increasing demand for precision control and enhanced reliability in process automation.

Automated valves not only streamline operations but also significantly reduce manual labor costs and the potential for human error. Furthermore, a study by the International Society for Automation (ISA) revealed that implementing automated valve systems can lead to energy savings of up to 30%, making them a vital component for companies aiming to optimize their resource management.

In this guide, we will explore strategies to effectively utilize automated valves to boost system efficiency and drive sustainable practices within your operations.

Understanding Automated Valves and Their Role in System Efficiency

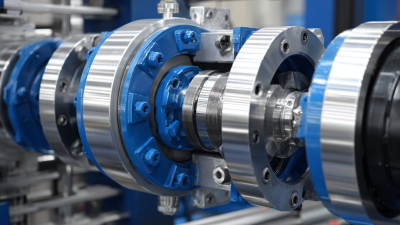

Automated valves are essential components in various industrial systems, playing a pivotal role in enhancing operational efficiency. These valves utilize control technologies to regulate the flow of fluids automatically, significantly reducing the need for manual intervention. By employing sensors and actuators, automated valves can respond swiftly to changes in system conditions, ensuring optimal performance and minimizing waste. This automation not only streamlines process control but also contributes to maintaining safety and reliability in operations.

Incorporating automated valves into system design allows for precise control over fluid dynamics, which is crucial for processes requiring strict adherence to parameters. This precision results in energy savings, as systems can operate at optimal levels without unnecessary energy expenditure. Moreover, automated valves can improve system responsiveness, allowing for quicker adjustments to fluctuations in demand or process variables. Overall, understanding the function and advantages of automated valves can lead to significant improvements in the efficiency and productivity of industrial systems.

Identifying Key Performance Indicators for Valve Optimization

Identifying key performance indicators (KPIs) for automated valve optimization is crucial for enhancing system efficiency. Firstly, flow rate serves as a fundamental KPI, as it directly impacts the throughput of a system. Monitoring the flow rate allows for timely adjustments to valve positions, ensuring that the system operates within desired parameters. Additionally, pressure drop across the valve is another significant KPI; a higher pressure drop may indicate blockages or inefficiencies that require attention. Tracking these metrics helps in pinpointing areas that need improvement.

Identifying key performance indicators (KPIs) for automated valve optimization is crucial for enhancing system efficiency. Firstly, flow rate serves as a fundamental KPI, as it directly impacts the throughput of a system. Monitoring the flow rate allows for timely adjustments to valve positions, ensuring that the system operates within desired parameters. Additionally, pressure drop across the valve is another significant KPI; a higher pressure drop may indicate blockages or inefficiencies that require attention. Tracking these metrics helps in pinpointing areas that need improvement.

Another important KPI is the response time of valves. Analyzing how quickly valves can adjust in response to system demands or control signals is essential for maintaining system responsiveness. Delays in valve response can lead to over or under-processing, ultimately affecting product quality and energy consumption. Finally, valve wear and failure rates should also be monitored as part of a comprehensive KPI framework. By establishing a robust set of KPIs, organizations can make data-driven decisions that lead to more efficient valve operations and overall system performance.

Best Practices for Installing Automated Valves in Your System

The installation of automated valves is essential for enhancing system efficiency, especially in high-demand environments such as dairy processing plants. As industry standards, particularly those outlined in the ISA-75 series, guide the design and testing of control valves, adhering to these benchmarks can significantly improve plant safety and operational efficiency. Automated valves not only streamline processes but also reduce the risk of human error, which is crucial in environments where precision and safety are paramount.

When implementing automated valves, it is vital to consider factors such as proper sizing and compatibility with existing systems. Research shows that optimized valve configurations can lead to energy savings and reduced downtime. Furthermore, integrating smart sensors with automated valves enhances data integrity, enabling real-time monitoring and adjustments that align with operational demands. With the ongoing evolution of automated solutions in the industry, embracing best practices for installation can drive significant improvements in productivity and safety across the board.

How to Optimize Your System Efficiency with Automated Valves - Best Practices for Installing Automated Valves in Your System

| Valve Type | Control Method | Power Supply | Typical Application | Efficiency Improvement (%) |

|---|---|---|---|---|

| Ball Valve | Electric Actuator | 24V DC | Water Supply Systems | 20% |

| Gate Valve | Pneumatic Actuator | Compressed Air | Oil & Gas Pipelines | 15% |

| Globe Valve | Hydraulic Actuator | Hydraulic Fluid | Chemical Processing | 25% |

| Check Valve | Gravity Actuated | N/A | Wastewater Treatment | 10% |

| Pressure Relief Valve | Electromechanical Actuator | 220V AC | Steam Systems | 18% |

Regular Maintenance Strategies for Prolonging Valve Lifespan

Regular maintenance is crucial for prolonging the lifespan of automated valves, which are integral to optimizing system efficiency in various industrial applications. According to the Valve Manufacturers Association, regular inspections can prevent up to 80% of valve failures, significantly reducing downtime and operational costs. Implementing a systematic maintenance schedule that includes checking for leaks, ensuring proper alignment, and examining actuator functionality can help identify potential issues before they escalate.

In addition, utilizing predictive maintenance strategies can greatly enhance valve longevity. Data from a recent report by the International Society of Automation highlights that predictive maintenance techniques can reduce maintenance costs by approximately 30% while extending equipment life by up to 25%. By employing advanced monitoring technologies, such as vibration analysis and thermal imaging, facilities can anticipate mechanical failures, ensuring valves operate at peak efficiency for extended periods. Regular maintenance not only optimizes performance but also safeguards investments in automated systems.

Integrating Automation Technologies for Enhanced Control and Monitoring

Automating valve systems in industrial settings not only improves operational efficiency but also significantly enhances control and monitoring capabilities. By integrating advanced automation technologies, businesses can achieve real-time oversight and seamless management of fluid dynamics in their processes. This enhances accuracy and reduces downtime, allowing for more responsive adjustments to any fluctuations in system performance.

Tips: One effective approach to integrate automation technologies is to leverage smart sensors that provide immediate feedback on valve performance. These sensors can proactively identify issues before they escalate, ensuring smooth operations. Additionally, employing centralized control systems allows operators to monitor multiple valves from a single interface, streamlining management and enabling quick decision-making.

Incorporating predictive maintenance algorithms into your valve automation can also result in significant efficiency gains. By analyzing data collected from automated systems, businesses can predict failures before they occur. This foresight not only minimizes costly interruptions but also extends the lifespan of the valves, leading to a more sustainable operation. Integrating these technologies fosters a culture of proactive maintenance, where potential issues are addressed before they impact overall system performance.

System Efficiency Optimization with Automated Valves

This chart illustrates the efficiency ratings of different types of automated valves, highlighting the impact of automation technologies on system performance. Higher ratings indicate better performance and control capabilities.

Related Posts

-

Essential Control Valves Maintenance Checklist for Optimal Performance

-

Unlocking Performance with Best Stainless Steel Valves Comprehensive Technical Parameters and How to Choose the Right Fit

-

Common Issues Faced by Gate Valves in High Pressure Applications

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

5 Essential Tips for Choosing the Right Cast Iron Butterfly Valve

-

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications