Understanding Pressure Valves and Their Impact on Industrial Safety

In the industrial landscape, the critical role of pressure valves cannot be overstated, as they are essential components that help maintain safety and operational efficiency across various sectors. According to a recent report from the Occupational Safety and Health Administration (OSHA), improper pressure control can lead to catastrophic failures, accounting for over 45% of industrial accidents annually.

Pressure valves serve as a first line of defense against overpressure situations, ensuring that systems operate within safe limits. Their functionality not only protects equipment but also safeguards personnel and the environment from hazardous incidents.

Pressure valves serve as a first line of defense against overpressure situations, ensuring that systems operate within safe limits. Their functionality not only protects equipment but also safeguards personnel and the environment from hazardous incidents.

In this blog, we will delve into the intricacies of pressure valves, explore their various types and applications, and provide actionable insights on best practices to enhance industrial safety. Understanding these critical devices is paramount for any organization aiming to foster a proactive safety culture and mitigate risk in high-pressure environments.

The Role of Pressure Valves in Maintaining Industrial Safety Standards

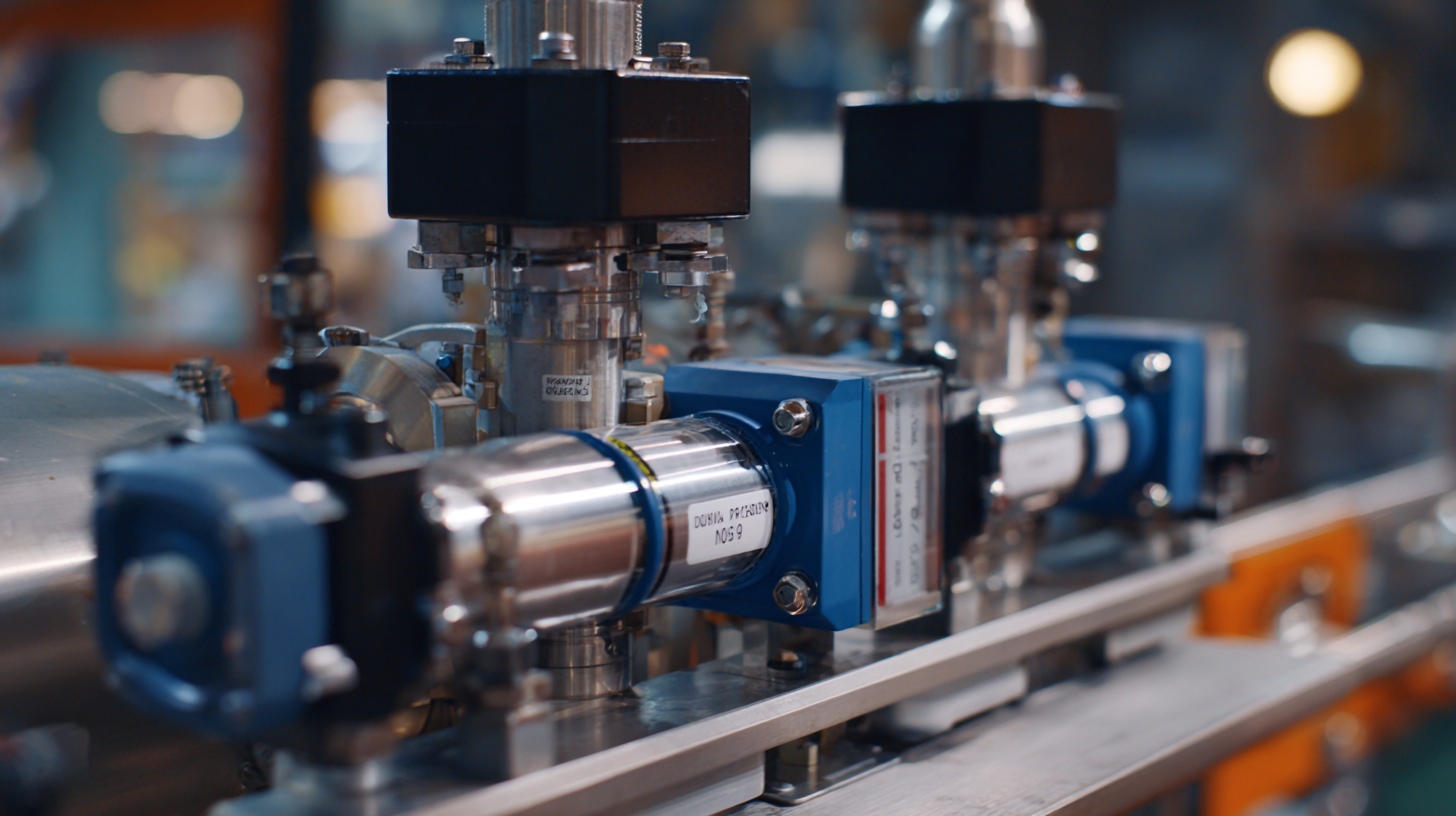

Pressure valves are critical components in industrial settings, playing a pivotal role in maintaining safety standards. These valves are designed to control and regulate the pressure within systems, ensuring that operations remain within safe limits. By releasing excess pressure, they prevent catastrophic failures that could lead to accidents, injuries, or extensive property damage.

In industries like manufacturing, oil and gas, and chemical processing, the functionality of pressure valves directly influences workplace safety.

Pressure valves are critical components in industrial settings, playing a pivotal role in maintaining safety standards. These valves are designed to control and regulate the pressure within systems, ensuring that operations remain within safe limits. By releasing excess pressure, they prevent catastrophic failures that could lead to accidents, injuries, or extensive property damage.

In industries like manufacturing, oil and gas, and chemical processing, the functionality of pressure valves directly influences workplace safety.

Moreover, the selection and maintenance of pressure valves are essential for compliance with industrial safety regulations. Regular inspections and timely replacements help to avoid malfunctions that could compromise safety. Understanding the specifications and capabilities of different types of pressure valves allows engineers to design systems that effectively mitigate risks. As industrial processes evolve and expand, the importance of robust pressure management through proper valve implementation remains paramount for both operational efficiency and worker safety.

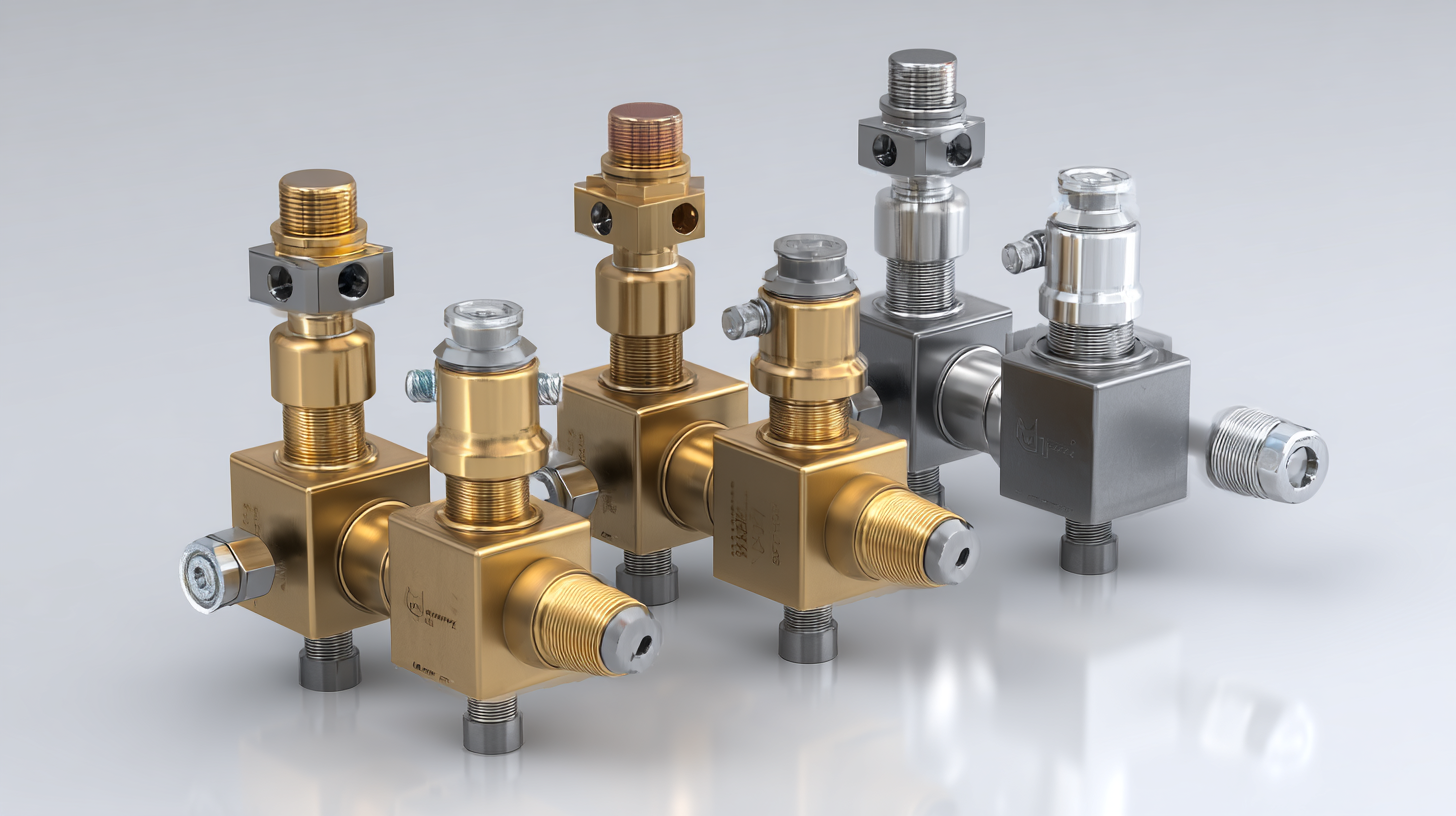

Types of Pressure Valves and Their Specific Applications in Industries

Pressure valves play a crucial role in ensuring industrial safety across various sectors, including oil and gas, manufacturing, and chemical processing. According to a report by MarketsandMarkets, the global pressure relief valve market is projected to grow from $3.5 billion in 2021 to $4.6 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.5%. This growth highlights the increasing reliance on advanced pressure management solutions to prevent accidents and ensure operational efficiency.

Different types of pressure valves serve specific applications tailored to industry needs. For example, safety relief valves are essential in petrochemical plants, where they manage excess pressure to prevent catastrophic failures. The American Petroleum Institute (API) states that improper pressure management can cause serious plant incidents, contributing to more than 33% of industrial accidents. Similarly, control valves are widely used in HVAC systems to regulate pressure and ensure optimal performance, echoing findings from the International Society of Automation that emphasizes the importance of precise pressure control in energy efficiency and system reliability.

In the food and beverage industry, pressure vacuum valves are critical for maintaining safe storage conditions for liquids. A report from the Food and Drug Administration (FDA) underscores that maintaining appropriate pressure levels helps prevent spoilage and ensures product safety. Each type of pressure valve has a unique role, underscoring the need for industries to prioritize proper valve selection and maintenance to uphold the highest safety standards.

Understanding Pressure Valves and Their Impact on Industrial Safety

Common Failures of Pressure Valves and Their Consequences on Safety

Pressure valves play a crucial role in maintaining safety within industrial environments. However, common failures of these valves can lead to significant safety hazards. For instance, a malfunctioning pressure relief valve may fail to release excess pressure, resulting in catastrophic system overloads. Such failures can cause equipment damage, environmental spills, and even severe injuries to personnel. The repercussions of these incidents can be long-lasting, affecting not just the immediate work environment but also the overall operational integrity of the facility.

Another prevalent issue is valve leakage, which can arise from corrosion, wear, or improper maintenance. Leakage compromises the containment of hazardous substances, increasing the risk of exposure to toxic chemicals for workers and nearby communities. This not only threatens human health but also poses substantial regulatory and financial repercussions for businesses. By recognizing these common failures, industries can implement proactive measures, such as regular inspection and maintenance protocols, to mitigate risks and enhance workplace safety. Understanding the potential impact of pressure valve failures is essential for fostering a culture of safety within industrial operations.

Industry Statistics on Pressure Valve Failures and Safety Incidents

Pressure valves play a critical role in maintaining safety standards across various industrial sectors. Recent industry statistics reveal alarming trends regarding pressure valve failures and their significant contribution to safety incidents. In particular, studies show that approximately 30% of industrial accidents are linked to valve malfunctions, underscoring the necessity for rigorous monitoring and maintenance practices. High-pressure systems, if not properly managed, can lead to catastrophic failures, resulting in injury, loss of life, and extensive property damage.

Furthermore, the economic impact of pressure valve failures is staggering. Industries face millions of dollars in lost productivity and repair costs after a single incident. The oil and gas sector, for instance, reports that nearly one-third of its safety incidents stem from valve-related issues. With these alarming figures, the importance of investing in quality pressure valves and comprehensive training for personnel cannot be overstated. By prioritizing the integrity and functionality of pressure valves, companies not only enhance operational efficiency but also significantly reduce the risk of accidents, thereby ensuring a safer working environment for all.

Best Practices for Pressure Valve Maintenance and Safety Compliance

Pressure valves are critical components in maintaining safety and efficiency in various industrial applications. According to the National Institute for Occupational Safety and Health (NIOSH), approximately 50% of major industrial accidents are linked to equipment failures, including malfunctioning pressure valves. Therefore, proper maintenance of these valves is not just a regulatory requirement but an essential practice to ensure workplace safety.

To achieve optimal performance, best practices for pressure valve maintenance should be implemented regularly. This includes routine inspections, testing, and the replacement of aging components. The American Society of Mechanical Engineers (ASME) recommends establishing a preventive maintenance program tailored specifically to the operational environment of the valves. Data from the International Society for Automation (ISA) shows that companies that adhere to structured maintenance schedules see a 20% reduction in equipment failure rates.

Additionally, staying compliant with industry standards, such as the American National Standards Institute (ANSI) regulations, is crucial. These standards provide comprehensive guidelines for the proper installation, operation, and maintenance of pressure valves. Regular training for personnel on these safety protocols can further mitigate risks. According to a report by the Occupational Safety and Health Administration (OSHA), companies that prioritize training programs experience significantly fewer accidents, underscoring the critical link between proper valve maintenance and overall industrial safety.

Understanding Pressure Valves and Their Impact on Industrial Safety - Best Practices for Pressure Valve Maintenance and Safety Compliance

| Aspect | Details | Best Practices | Compliance Standards |

|---|---|---|---|

| Type of Pressure Valve | Safety Valve | Regular testing and calibration | ASME BPVC Section I |

| Common Issues | Leakage, Blockage | Routine inspections | OSHA Safety Regulations |

| Maintenance Frequency | Quarterly | Document all maintenance activities | API Recommended Practices |

| Training Requirements | Operator Training | Hands-on training and certifications | ANSI/ISA Standards |

| Documentation Needed | Maintenance Logs, Inspection Records | Maintain up-to-date records | ISO 9001 |

Related Posts

-

Unlocking Performance with Best Stainless Steel Valves Comprehensive Technical Parameters and How to Choose the Right Fit

-

Innovative Examples of Stainless Steel Ball Valves Enhancing Efficiency in Industrial Applications

-

How to Select the Best Actuated Butterfly Valve for Optimal Process Efficiency in Global Industries

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

Essential Control Valves Maintenance Checklist for Optimal Performance

-

Ultimate Guide to Choosing the Right Electric Valves for Your Industrial Needs