Innovative Examples of Stainless Steel Ball Valves Enhancing Efficiency in Industrial Applications

In the fast-paced world of industrial operations, the demand for reliable and efficient fluid control systems has never been greater. According to a recent report by the Global Valve Market, the market for stainless steel ball valves is projected to reach USD 12 billion by 2025, underscoring their vital role in various sectors, including oil and gas, chemical processing, and water treatment.

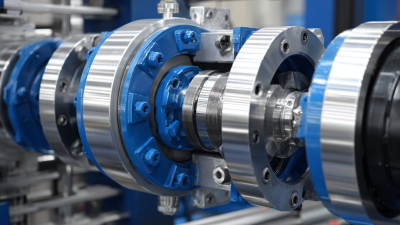

These valves, renowned for their durability, resistance to corrosion, and ease of maintenance, are becoming increasingly sophisticated through innovative designs and technology integrations. The latest advancements not only enhance their performance but also contribute significantly to energy efficiency and operational sustainability. As industries continue to seek solutions that promote efficiency and cost-effectiveness, stainless steel ball valves stand out as a crucial component in achieving these objectives.

These valves, renowned for their durability, resistance to corrosion, and ease of maintenance, are becoming increasingly sophisticated through innovative designs and technology integrations. The latest advancements not only enhance their performance but also contribute significantly to energy efficiency and operational sustainability. As industries continue to seek solutions that promote efficiency and cost-effectiveness, stainless steel ball valves stand out as a crucial component in achieving these objectives.

Advantages of Stainless Steel Ball Valves in Industrial Settings

Stainless steel ball valves are playing a pivotal role in enhancing efficiency across various industrial applications. One of the primary advantages of these valves is their durability, which is backed by the high resistance to corrosion and oxidation exhibited by stainless steel. According to a report by MarketsandMarkets, the global stainless steel valve market is expected to reach $16.22 billion by 2025, highlighting the increasing reliance on stainless steel components in critical operations. This material not only extends the lifespan of the valves but also reduces maintenance costs, making them a cost-effective solution for industries like oil and gas, water treatment, and food processing.

Another significant advantage of stainless steel ball valves is their superior flow control capabilities. Their design, featuring a spherical ball with a bore, allows for minimal resistance to flow, which translates to higher efficiency in fluid and gas transport. Research from the International Journal of Engineering Research and Technology indicates that ball valves can offer a flow coefficient (Cv) that is typically 50% higher than that of gate valves, leading to reduced energy consumption and improved process performance. This efficiency not only optimizes the operational capabilities of industrial systems but also contributes to sustainability goals by minimizing waste and energy use in production processes.

Innovative Examples of Stainless Steel Ball Valves Enhancing Efficiency

Enhancing Flow Control: Innovative Designs in Ball Valve Technology

Stainless steel ball valves have revolutionized flow control in industrial applications, thanks to innovative designs that enhance efficiency and reliability. These valves are known for their durability and resistance to corrosion, making them ideal for various environments, including chemical processing and oil and gas industries. According to a report by MarketsandMarkets, the global market for industrial valves is projected to reach $89.2 billion by 2027, with ball valves representing a significant segment due to their superior performance and flow characteristics.

Recent advancements in ball valve technology, such as the development of multi-port designs and actuated systems, have further improved flow control. These innovations facilitate precise regulation of fluid dynamics, reducing energy consumption and operational costs. For instance, a study published by the American Society of Mechanical Engineers (ASME) found that using advanced ball valves can enhance flow efficiency by up to 30%, significantly impacting overall process optimization. Such efficiencies not only lead to cost savings but also contribute to environmental sustainability by minimizing waste and energy use.

Innovative Examples of Stainless Steel Ball Valves Enhancing Efficiency in Industrial Applications

| Application Area | Valve Type | Size (Inches) | Max Pressure (psi) | Temperature Range (°F) | Efficiency Improvement (%) |

|---|---|---|---|---|---|

| Chemical Processing | Full Port | 2 | 300 | -20 to 250 | 15 |

| Oil & Gas | Trunnion Mounted | 3 | 600 | -40 to 300 | 20 |

| Water Treatment | Standard | 4 | 150 | 32 to 140 | 10 |

| Food Processing | Sanitary | 1.5 | 100 | -10 to 200 | 12 |

| Pharmaceuticals | Electric Actuated | 2.5 | 250 | -20 to 300 | 18 |

Energy Efficiency: How Stainless Steel Valves Reduce Operational Costs

Stainless steel ball valves have emerged as a crucial component in enhancing energy efficiency across various industrial applications. Their design, featuring a smooth bore and minimal flow resistance, allows for seamless fluid dynamics that diminish the energy required for pumping and operation. By reducing friction and ensuring that fluids flow freely, these valves significantly lower the operational costs associated with energy consumption. Industries ranging from oil and gas to food processing are witnessing notable reductions in their energy bills, thanks to the efficiency these valves bring to their systems.

Moreover, stainless steel's durability and resistance to corrosion ensure that these ball valves maintain their performance over time, further contributing to long-term savings.

Unlike traditional valve materials that may require frequent replacement due to wear and tear, stainless steel valves offer longevity and reliability. This not only minimizes the need for costly repairs and replacements but also reduces downtime, allowing businesses to operate more efficiently. Ultimately, integrating stainless steel ball valves into industrial processes is a smart move towards achieving greater energy efficiency and reduced operational costs.

Automation Integration: Smart Solutions with Stainless Steel Ball Valves

The rise of automation in industrial applications has ushered in a new era of efficiency, and stainless steel ball valves are at the forefront of this transformation. These robust valves not only offer extreme durability and corrosion resistance but also integrate seamlessly with automated systems. By employing smart controls, industries can enhance operational precision while reducing the risk of leaks and failures, ultimately leading to increased uptime and reduced maintenance costs.

Moreover, the incorporation of sensors and telemetry in stainless steel ball valves allows for real-time monitoring of fluid dynamics within pipelines. This data-driven approach empowers facility managers to make informed decisions, optimize processes, and anticipate maintenance needs before potential failures occur. As industries move toward a more connected environment, the role of stainless steel ball valves equipped with automation technology will undoubtedly become more critical, driving continuous improvement and sustainability in various sectors.

Case Studies: Real-World Applications of Enhanced Valve Performance

In recent years, stainless steel ball valves have revolutionized efficiency in various industrial applications, demonstrating notable improvements in performance across several case studies. For instance, a report by the International Association of Plumbing and Mechanical Officials (IAPMO) highlights that industries utilizing advanced stainless steel ball valve technology have reported up to a 30% decrease in energy consumption. This significant reduction is attributed to the valve's ability to maintain a consistent flow rate while minimizing pressure drops.

In recent years, stainless steel ball valves have revolutionized efficiency in various industrial applications, demonstrating notable improvements in performance across several case studies. For instance, a report by the International Association of Plumbing and Mechanical Officials (IAPMO) highlights that industries utilizing advanced stainless steel ball valve technology have reported up to a 30% decrease in energy consumption. This significant reduction is attributed to the valve's ability to maintain a consistent flow rate while minimizing pressure drops.

One remarkable case comes from a food processing plant that integrated stainless steel ball valves into its systems. By replacing traditional valves, the facility not only enhanced productivity by 25% but also adhered to stringent hygiene standards, which are crucial in the food industry. Enhanced design features, such as better sealing and corrosion resistance, contributed to longer service intervals and reduced maintenance costs—factors that can save manufacturers substantial amounts annually.

Tip: When selecting stainless steel ball valves, look for those with third-party certifications, ensuring their performance and safety standards meet industry regulations. Additionally, consider valves with lower torque requirements to improve actuator efficiency and further reduce energy costs.

Related Posts

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

Ultimate Guide to Choosing the Right Electric Valves for Your Industrial Needs

-

Common Issues Faced by Gate Valves in High Pressure Applications

-

How to Select the Best Actuated Butterfly Valve for Optimal Process Efficiency in Global Industries

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

Unlocking Performance with Best Stainless Steel Valves Comprehensive Technical Parameters and How to Choose the Right Fit